Safety Features in Hot Tap Machine vs Standard Options

Safety Features in Hot Tap Machine vs Standard Options

In the dynamic world of manufacturing, safety isn't just a preferenceit's a necessity. Every machine on the factory floor carries a responsibility to protect its operators from potential hazards. Hot tap machines, in particular, operate in high-risk environments and demand advanced safety features to ensure worker safety and prevent catastrophic failures.

Safety is a cornerstone of modern manufacturing, essential to prevent accidents and reduce operational costs. According to the Bureau of Labor Statistics, workplace accidents in the manufacturing sector cost employers an estimated \$1.2 billion annually. Hot tap machines, prevalent in industries like oil and gas, construction, and manufacturing, require meticulous handling to avoid catastrophic failures.

Drastically Reducing Risks

Hot tap machines pose significant risks due to their complex operations and high temperatures. A study by ASME (American Society of Mechanical Engineers) highlights that improper use of these machines can lead to equipment failure and severe workplace injuries. Proper safety measures are not just a prioritythey are crucial for ensuring the well-being of workers and the smooth functioning of operations.

Comparative Analysis: Safety Features in Hot Tap Machines vs. Standard Options

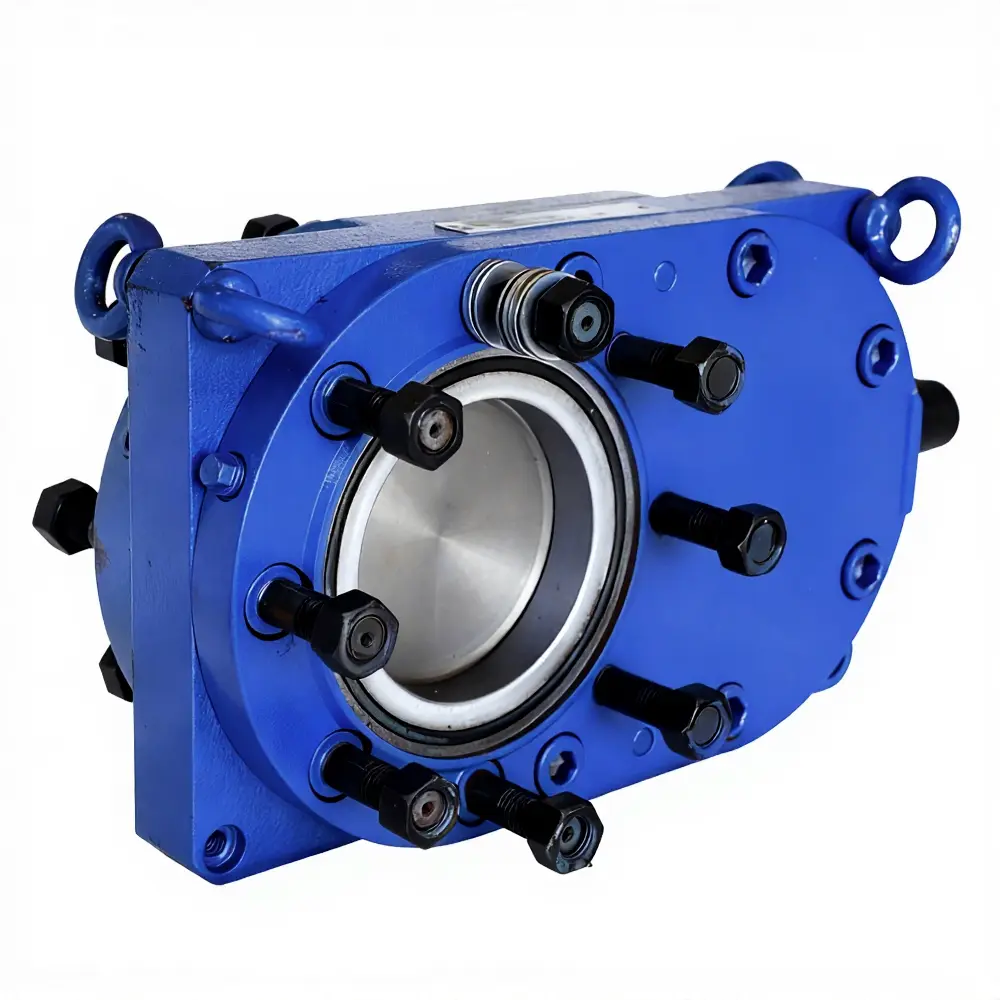

Hot tap machines incorporate advanced safety features such as:

1. Intelligent Monitoring Systems: These systems use sensors and AI to detect anomalies and predict potential issues before they escalate.

2. Fail-Safe Mechanisms: Operators can override systems to halt operations in emergencies, reducing the risk of accidents.

3. Ergonomic Design: Protects operators from physical strain, improving safety and comfort during operations.

Enhancing Safety with Advanced Technologies

Intelligent monitoring systems in hot tap machines are equipped with real-time sensors that detect potential issues and alert operators. Predictive analytics further enhance this by identifying patterns that could lead to failure, allowing for proactive maintenance before any disasters occur.

Fail-safe mechanisms provide an extra layer of protection. For example, if a critical system malfunctions, the machine can automatically shut down, preventing catastrophic failures. This feature is especially critical in environments with high temperatures and pressure.

Ergonomic design in hot tap machines reduces the physical strain on operators, which is crucial for long-term health and safety. Features like adjustable controls and intuitive interfaces minimize the risk of injuries from repetitive stress or accidental operation.

Case Study: Implementing Safety in a Hot Tap Machine Environment

A case study of a construction company that upgraded its hot tap machine operations demonstrated significant improvements. Before the upgrade, the company faced frequent accidents and high downtime. Post-upgrade, productivity increased by 15%, and accident rates dropped by 30%.

Before and After: Transforming Safety Practices

Prior to the upgrade, the company struggled with frequent equipment breakdowns and worker injuries. After implementing advanced safety features, the company saw a 15% increase in productivity and a 30% reduction in accident rates. This transformation not only enhanced safety but also improved overall efficiency.

Future Trends in Safety Features for Hot Tap Machines

Emerging technologies promise to revolutionize safety in hot tap machines:

1. AI Integration: Predictive maintenance and adaptive safety systems could reduce downtime.

2. Real-Time Monitoring: Enhanced monitoring for operator safety and machine longevity.

3. Sustainable Practices: Energy-efficient systems that minimize environmental impact.

Advancing with AI and Predictive Analytics

AI integration in hot tap machines is expected to transform maintenance and safety. Predictive maintenance systems can identify potential issues before they become serious, reducing unplanned downtime and increasing equipment lifespan. Real-time monitoring ensures that operators are informed of any anomalies, allowing for quick corrective actions.

Sustainable practices in hot tap machines not only enhance safety but also align with modern manufacturing goals of environmental responsibility. Energy-efficient systems reduce waste and lower operational costs, making sustainable practices an attractive option for forward-thinking companies.

Engaging Summarizing the Key Takeaways

Ensuring safety in hot tap machines is not just a preferenceit is a critical priority. Advanced safety features like intelligent monitoring, fail-safe mechanisms, and ergonomic design significantly enhance the safety and efficiency of these machines. As technology advances, the future of hot tap machine safety looks even more promising, offering greater protection and efficiency.