Optimal Applications of Pipe Hot Tap Machines Across Industries

Optimal Applications of Pipe Hot Tap Machines Across Industries

In the modern industrial landscape, the seamless integration of technologies and tools is crucial for maintaining reliability and efficiency. Pipe hot tap machines stand out as indispensable tools, especially in industries where precision and durability are paramount.

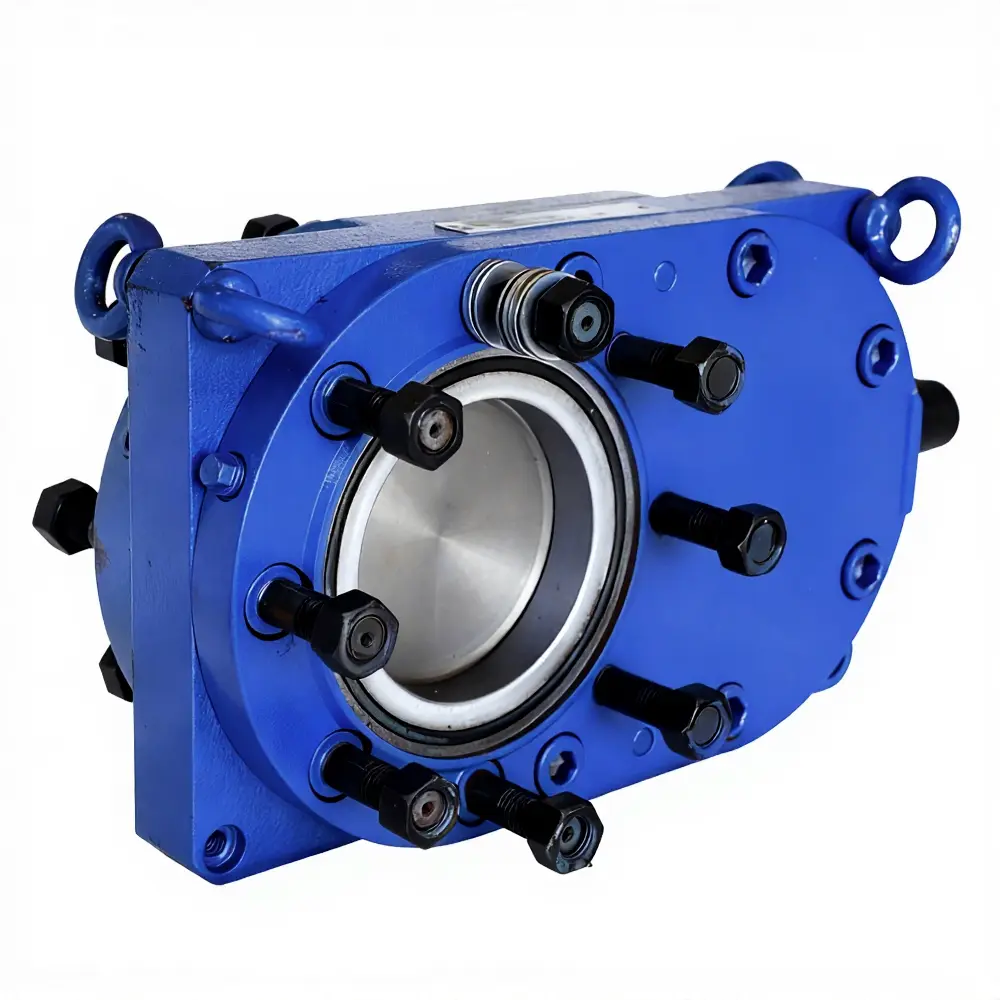

Pipe hot tap machines are specialized tools designed to join pipes by heating and cooling them to create a permanent bond. These machines come in various types, including air-actuated, water-actuated, and oil-actuated systems, each suited to different applications based on pressure requirements.

The Basics of Pipe Hot Tap Machines

Pipe hot tap machines are versatile and essential in various industries. Air-actuated systems are ideal for lower pressure environments, offering cost-effectiveness and ease of operation. Water-actuated systems handle higher pressure applications with better stability and efficiency. Oil-actuated systems provide the greatest stability and can manage a wider range of pressures, making them suitable for demanding environments.

Applications in Construction

In construction, pipe hot tap machines are crucial for laying and reinforcing pipeline infrastructure. They ensure strong, pressure-resistant connections, which are essential in highway and railway construction. For example, in highway projects, these machines create stable foundations for pipelines, ensuring that the infrastructure can withstand traffic and environmental conditions.

In urban renewal projects, pipe hot tap machines are used to upgrade old pipelines, improving the reliability of water and gas distribution systems. They help in creating modern, pressure-resistant solutions that enhance the durability and longevity of the infrastructure. Precision is key here, ensuring all components are perfectly aligned to prevent leaks and extend the lifespan of the infrastructure.

Applications in Manufacturing

In manufacturing, pipe hot tap machines are indispensable for producing high-quality pipes used in heavy machinery and other industrial applications. Their precision ensures that pipes are joined seamlessly, meeting the highest standards of quality and durability. This is particularly important in industries like automotive and aerospace, where even minor imperfections can lead to catastrophic failures.

Quality control benefits significantly from pipe hot tap machines. By ensuring each joint is perfectly formed, these machines reduce the risk of defects, which improves efficiency and reduces waste. Enhanced product quality and minimized downtime and repair costs are direct outcomes of their use.

Applications in Energy and Utilities

In the energy and utilities sector, pipe hot tap machines play a vital role. They are used in oil and gas exploration and production to create strong casings that guide drilling fluids and equipment safely into the earth. Precision is critical in this sector to prevent accidents and minimize environmental damage.

In utility infrastructure development, these machines help upgrade old systems, improving reliability and efficiency. By replacing outdated infrastructure with modern, pressure-resistant solutions, they help reduce energy losses and ensure a more reliable supply of utilities. This contributes to the overall sustainability of energy distribution, minimizing waste and maximizing efficiency.

Applications in Emerging Markets

In developing countries, pipe hot tap machines are increasingly used to support infrastructure development projects. They provide affordable and durable solutions for building and upgrading pipeline infrastructure, driving economic growth and improving the quality of life for communities. By ensuring pipes are joined securely and under pressure, these machines contribute to the reliability and longevity of infrastructure projects.

Sustainability is a key priority in emerging markets, and pipe hot tap machines play a crucial role in promoting sustainable infrastructure. They prevent leaks and reduce the environmental impact of construction projects, contributing to the development of sustainable systems that benefit both communities and the environment.

Conclusion

Pipe hot tap machines are a versatile and essential tool for modern industries, offering a wide range of applications that contribute to the success of construction, manufacturing, energy, and utilities projects. As technology continues to evolve, these machines will remain a key driver of efficiency, reliability, and sustainability, ensuring they play a central role in shaping the future of industrial infrastructure.

Additional Tips for Using Pipe Hot Tap Machines

- Ensure the machine is suitable for the specific application and pressure requirements.

- Follow precise installation and operating procedures to maintain safety and efficiency.

- Regular maintenance and inspection are crucial to prolong the lifespan and performance of the machine.

In conclusion, pipe hot tap machines are indispensable for ensuring reliable and durable infrastructure across various industries. Their precision and versatility make them a cornerstone of modern industrial processes, driving efficiency, reliability, and sustainability.