How to Install Commercial Hot Tap Machines Efficiently

Hot tap machines are indispensable in commercial applications, particularly in industries like oil and gas, water treatment, and chemical manufacturing. These machines allow technicians to make connections to pressurized pipelines without shutting down operations, thereby minimizing downtime and operational risks. The installation process requires a careful blend of precision, safety, and adherence to best practices. This article will guide you through the entire installation process, ensuring a smooth and efficient setup.

Introduction to Hot Tap Machines

Hot tap machines are specialized tools used to make connections to existing pipelines while they remain operational. This method is essential in industries like petrochemicals, water and wastewater, and gas transmission because it allows for the seamless integration of new systems or pipelines without disrupting ongoing operations. The ability to connect and disconnect lines while maintaining operational flow is crucial for industries where uptime is critical.

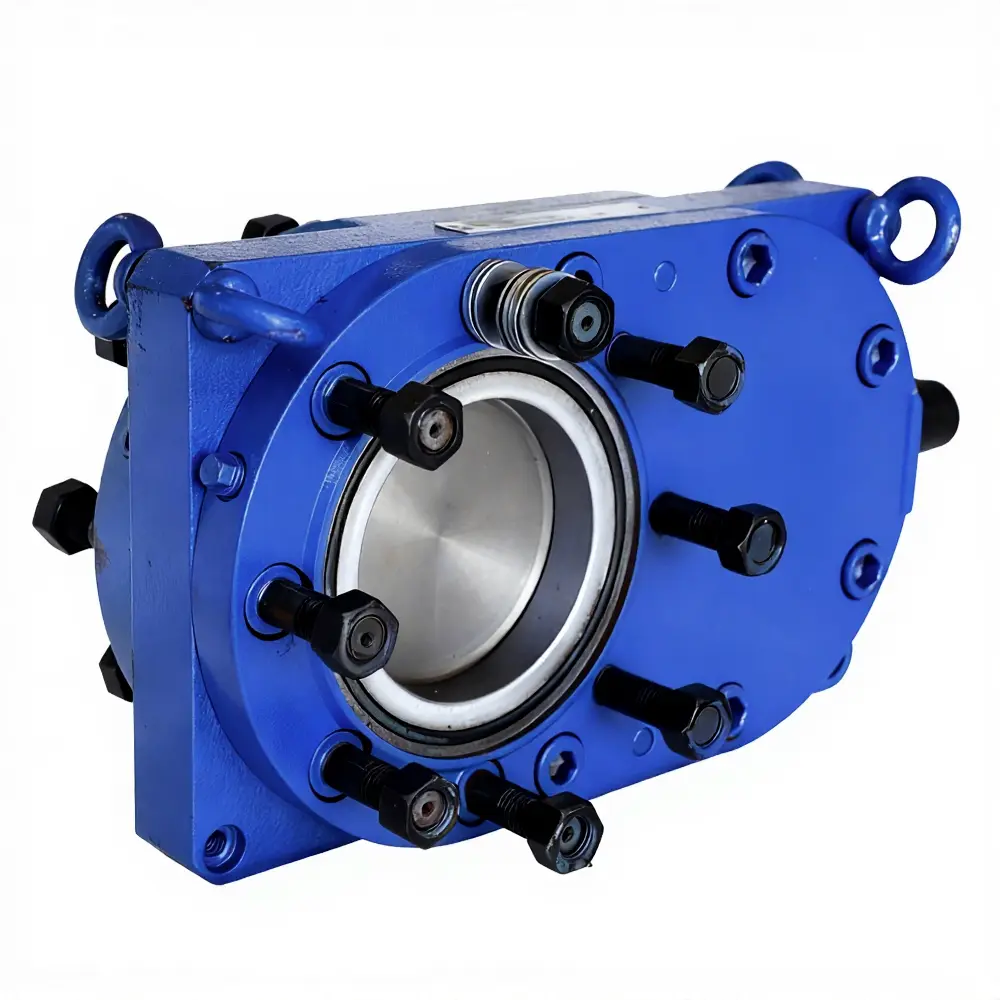

Hot tap machines come in various forms, including rotary cutting machines, thermal lance machines, and hydraulic ram machines, each suited to specific applications and conditions. Understanding the basic components and the overall process is fundamental to successfully installing these machines.

Understanding the Installation Process

Key Components of a Hot Tap Machine

- Cutting Tool: This can be a rotating cutter or a thermal lance for melting metal. The cutting tool is essential for making precise and safe connections.

- Valve Actuator: Used to isolate the pipeline during repairs or connections. Ensuring the pipeline is properly isolated is crucial for safety and preventing leaks.

- Pressure Seal System: Ensures a secure and leak-proof seal when making connections. The reliability of this system is paramount to maintaining operational integrity.

- Hydraulic System: Provides the necessary power to operate the machine. The hydraulic system must be functioning correctly to ensure the machine operates smoothly.

Safety Considerations Before Installation

- Training: Ensure all technicians are well-trained and familiar with the machine. Training is critical to prevent accidents and ensure safe operations.

- Permits and Approvals: Obtain necessary permits and approvals from regulatory bodies. Compliance with local regulations is essential for legal and safe operation.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including gloves, safety goggles, and protective clothing. Proper PPE protection is vital to ensure the safety of technicians during the installation process.

Step-by-Step Guide to Basic Installation

- Position the Machine: Carefully align the cutting tool with the pipeline. Precision is key to avoid damaging the pipeline.

- Secure the Machine: Use clamps or mounting brackets to secure the machine in place. Ensuring the machine is stable prevents it from moving during operation.

- Connect the Machine: Attach the machines components to the pipeline securely. Tightly sealing all connections is essential to prevent leaks.

- Pressure Test: Conduct a pressure test to ensure all connections are tight and leak-free. Leaks can cause significant operational issues.

- Operate the Machine: Activate the machine and proceed with the connection. Following the manufacturers guidelines ensures optimal performance.

Preparing the Worksite

Site Assessment

- Site Survey: Evaluate the pipeline's integrity and ensure it meets the machine's requirements. A thorough site survey is essential for a successful installation.

- Clear Work Area: Remove any obstacles and set up a clean, organized workspace. A clutter-free area enhances safety and efficiency.

Ensuring Proper Tools and Equipment

- Tool Kit: Have all required tools and spare parts readily available. A well-equipped tool kit ensures you can handle any unexpected issues.

- Safety Gear: Ensure all necessary safety equipment is present and in good condition. Proper PPE (Personal Protective Equipment) is essential for safety.

Setting Up a Safe Work Environment

- Compliance: Adhere to local safety regulations and industry standards. Compliance ensures legal and safe operations.

- Signage: Clearly mark the work area to alert other workers. Signage helps prevent accidents and ensures a safe work environment.

- Communication: Establish clear communication protocols among team members. Effective communication is key to coordinating the installation process.

Detailed Installation Procedures

Aligning the Machine with the Pipeline

- Carefully position the cutting tool over the desired connection point. Precise alignment is crucial to avoid damage.

- Ensure the Alignment is Perfect: A small misalignment can lead to significant issues during the connection process.

Securing the Machine

- Use clamps or mounting brackets to secure the machine in place. Ensuring the machine is stable prevents it from moving during operation.

- Double-Check: Double-check that the machine is securely mounted to avoid any accidents.

Connecting the Machine to the Pipeline

- Attach the machines components to the pipeline securely. Tightly sealing all connections is essential to prevent leaks.

- Tight Connections: Properly sealing all connections is critical to maintaining operational integrity.

Operational Checks and Testing

Performing Initial Checks Before Operation

- Pressure Gauge: Ensure all components are functioning properly. A functioning pressure gauge is essential for safe operation.

- Hydraulic System: Check for leaks and ensure the system is pressurized correctly. A properly functioning hydraulic system ensures smooth operation.

Testing the Machine

- Start the machine and observe for any leaks or malfunctions. Proper testing ensures the machine is ready for use.

- Adjust Settings: Adjust settings as necessary to ensure optimal performance. Fine-tuning the machine can improve its effectiveness and reliability.

Maintenance and Safety Tips

Regular Maintenance Requirements

- Cleanliness: Regularly clean the machine to remove debris and contaminants. A clean machine operates more efficiently and is less prone to issues.

- Inspection: Inspect all components for wear or damage. Regular inspections can help identify potential problems before they become serious.

- Documentation: Keep detailed records of maintenance activities. Documentation ensures that all maintenance activities are tracked and can be referenced when needed.

Safety Protocols

- Escalation Plan: Develop and document an escalation plan in case of emergencies. An escalation plan helps manage and resolve unexpected issues.

- Emergency Shutoff: Ensure the machine has a quick-shutoff mechanism. A quick-shutoff mechanism provides immediate safety in case of emergencies.

- Regular Training: Conduct regular safety training sessions for all team members. Regular training ensures that all personnel are up-to-date with safety protocols.

Troubleshooting Common Issues

- Machine Malfunctions: Refer to the machines manual for troubleshooting steps. Following the manual can help resolve most common issues.

- Overheating: Ensure proper ventilation and cooling systems are in place. Proper ventilation and cooling prevent overheating and extend the machines lifespan.

Successful Installations

Real-World Examples

- Case Study 1: A water treatment plant successfully installed a new pipeline using a hot tap machine, reducing downtime by 50%. This case demonstrates the effectiveness of hot tap machines in real-world applications.

- Case Study 2: An oil refinery utilized a hot tap machine to install a new fuel line, minimizing the risk of leaks and saving thousands in operational costs. This case highlights the financial and operational benefits of using hot tap machines.

Lessons Learned

- Proper Planning: Thorough planning and preparation are essential for a successful installation. Clear planning ensures that all necessary steps are covered.

- Employee Training: Well-trained technicians are essential for a safe and efficient installation. Training ensures that all personnel are knowledgeable and capable.

Comparisons of Different Installation Methods

- Comparative Analysis: Different installation methods, such as cold tapping or traditional shut-down methods, were compared. Hot tap machines proved to be more cost-effective and safer in most scenarios. This analysis provides valuable insights into the advantages of using hot tap machines.

Comparative Analysis: Different Types of Hot Tap Machines

Overview of Various Hot Tap Machine Types

- Rotary Cutting Machine: Suitable for larger diameter pipelines. These machines are versatile and can handle a wide range of applications.

- Thermal Lance Machine: Ideal for precision cuts and smaller pipelines. These machines provide precise cuts with minimal heat impact.

- Hydraulic Ram Machine: Provides high-pressure cutting for heavy-duty applications. These machines are durable and can handle intense cutting tasks.

Pros and Cons of Each Type

- Rotary Cutting Machine: Pros - Versatile, suitable for a wide range of applications. Cons - Can be more expensive.

- Thermal Lance Machine: Pros - Precise cuts, minimal heat impact. Cons - Limited to smaller diameter pipelines.

- Hydraulic Ram Machine: Pros - High-pressure cutting, durable. Cons - Requires more maintenance.

Recommendations for Specific Commercial Applications

- Petroleum: Thermal Lance Machine for precise, low-heat cuts. These machines are ideal for applications requiring minimal heat impact.

- Water Treatment: Rotary Cutting Machine for versatility and durability. These machines are well-suited for the demands of water treatment pipelines.

- Chemical Industries: Hydraulic Ram Machine for high-pressure applications. These machines are essential for handling the high pressures required in chemical industries.

Conclusion

Efficient installation of hot tap machines can significantly reduce downtime and operational costs, making it an essential tool for any commercial application involving pipelines. Whether you are in the oil and gas, water treatment, or chemical industries, understanding the installation process and adhering to best practices will lead to successful and reliable operations.