Top Differences in Pipe Hot Tap Machine Specs Explained

Pipe hot tapping is a critical process in the energy and utility industries. Understanding the key specifications of pipe hot tap machines is essential for operators and engineers to ensure reliability, safety, and efficiency. This article delves into cutting mechanisms, cooling systems, hydraulic systems, safety features, performance, cost considerations, environmental impact, and future trends. Each section is comprehensive and provides valuable insights to help make informed decisions.

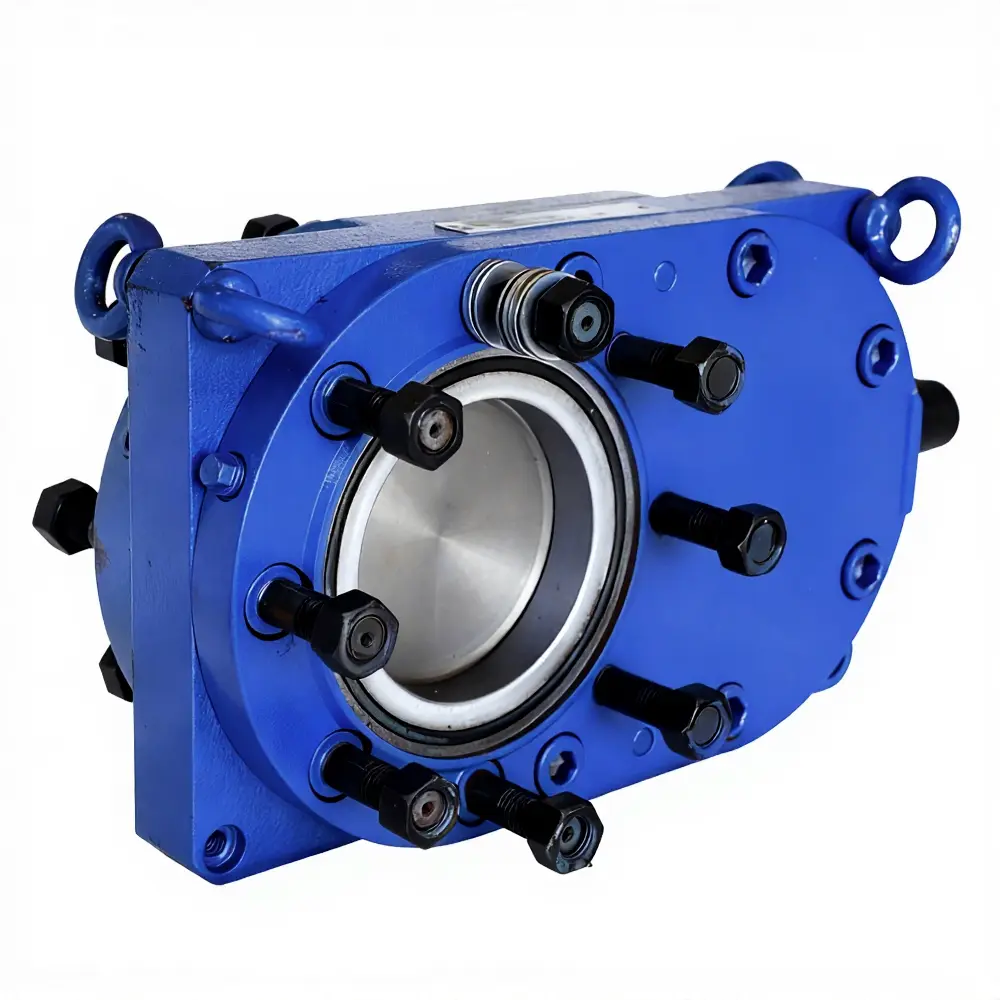

Cutting Mechanisms

The cutting mechanism is the heart of a pipe hot tap machine. High-pressure water jets, knives, and diamond-tipped cutting wheels are common. The choice depends on the pipe material and diameter.

Cooling Systems

Cooling systems keep the cutting area cool to avoid pipe damage. Water-based systems are standard, but air-cooling systems are also available, especially for large projects.

Hydraulic Systems

Hydraulic systems control the pressure and energy for cutting. Pumps and valves ensure smooth operation and safety. Advanced hydraulic systems offer better precision and faster cutting times.

Safety Features

Safety is paramount in pipe hot tap operations. Automated shut-off mechanisms, emergency stop buttons, and thermal sensors prevent accidents. Regular maintenance and safety training are also critical.

Performance

Performance metrics include cutting speed, temperature control, and machine durability. Higher-end models offer faster cutting times and better temperature control, although they come at a higher cost.

Cost Considerations

Cost factors include initial purchase price, maintenance, and operational expenses. Budgeting should consider not just the machine but also the associated costs of operation and maintenance.

Environmental Impact

Environmental impact is a growing concern. Energy-efficient machines and water recycling systems help reduce the carbon footprint. Sustainable practices are becoming increasingly important.

Future Trends

Future trends include the development of smarter machines with advanced sensors, AI for predictive maintenance, and greater integration with IoT. These advancements aim to enhance efficiency and safety.

By understanding these key specifications, operators and engineers can choose the most suitable pipe hot tap machine for their applications.