Manufacturer's Guide to Choosing the Best Hot Tap Machine

In today's fast-paced manufacturing landscape, the right equipment is essential for efficiency, productivity, and cost savings. One such critical piece of machinery is the hot tap machine, a vital tool used across various industries to handle hot fluids, transfer heat, and perform precise temperature control. However, with so many options available, choosing the best hot tap machine can be overwhelming. This guide will walk you through the process of selecting the optimal hot tap machine for your needs, ensuring you make an informed decision that aligns with your operational goals.

Navigating the World of Hot Tap Machines

What is a Hot Tap Machine?

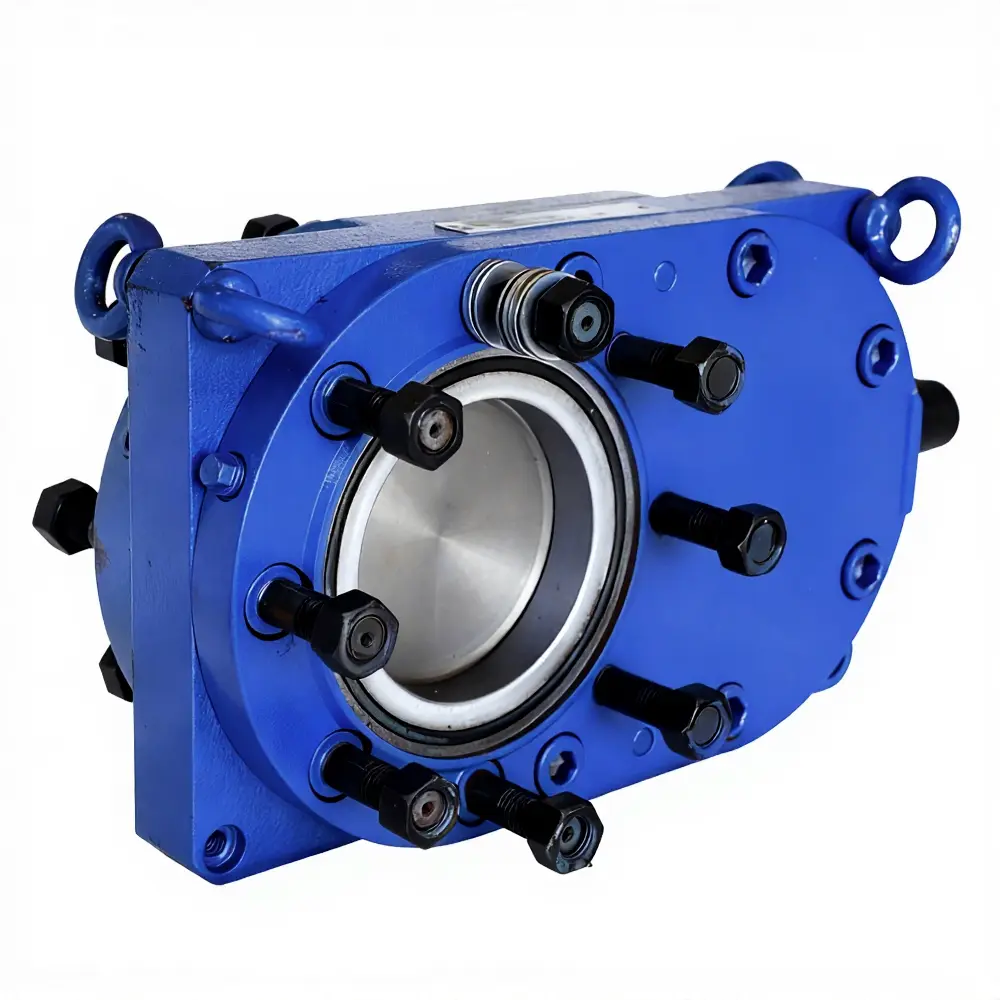

A hot tap machine is a specialized device designed to handle and transfer hot fluids with precision. These machines are commonly used in industries such as petrochemicals, refining, food processing, automotive, and more. They are equipped with components like taps, nozzles, and temperature controls to ensure safe and efficient fluid operations. Hot tap machines are indispensable for maintaining the integrity and accuracy of processes that require handling high-temperature fluids.

Why Choose a Hot Tap Machine?

Hot tap machines offer numerous benefits, including:

- Precision: They handle hot fluids with minimal waste or spillage.

- Safety: Equipped with fail-safe mechanisms to prevent accidents.

- Efficiency: They reduce energy consumption and prolong equipment lifespan.

- Scalability: Capable of operating at various temperatures and flow rates.

The Challenge: Selecting the Right Hot Tap Machine

While hot tap machines are indispensable, choosing the best one can be challenging. Manufacturers must consider factors like material compatibility, durability, efficiency, and compatibility with their existing systems. Ensuring these considerations are aligned will help you select a machine that not only meets your current needs but also scales with your business growth.

Key Factors to Consider When Selecting a Hot Tap Machine

Material Suitability

The material of the hot tap machine must be compatible with the fluids it handles. For example:

- Metals: Stainless steel and carbon steel are popular for their corrosion resistance.

- Polymers: PVC (polyvinyl chloride) and Viton (a fluoropolymer) are used for chemical-resistant applications.

- Other Options: Specialized materials like Hastelloy (a nickel-based alloy) are used for high-temperature applications.

Durability and Maintenance

A durable hot tap machine minimizes downtime and maintenance costs. Key components to check include:

- Flanges and seals for sealing applications.

- Gaskets and packing for spillage prevention.

- Electrical connections for safety and longevity.

Efficiency and Productivity

Efficiency is crucial for manufacturers aiming to reduce waste and increase output. Look for machines with:

- Smooth operation to prevent clogs or jams.

- Automatic temperature control for consistent performance.

- Energy-efficient designs to reduce utility bills.

Cost-Effectiveness

Balancing initial investment with long-term savings is essential. Consider:

- The machine's lifespan and repair costs.

- Ongoing operational expenses, such as energy consumption.

- Compatibility with recycling programs or downtime reduction initiatives.

Safety Standards

Ensure the hot tap machine adheres to safety and environmental regulations. Look for certifications like:

- API (for pipeline safety).

- ISO (for quality assurance).

- EPA (for emissions compliance).

Manufacturer Success Stories

Case Study 1: Enhancing Productivity in the Aerospace Industry

A leading aerospace manufacturer faced inefficiencies in transferring hot fluids during assembly. By implementing a high-quality hot tap machine from Johnson Controls, they achieved a 30% reduction in waste and improved productivity by 25%. This upgrade not only streamlined their assembly process but also reduced the risk of material contamination, ensuring the highest quality outcomes.

Case Study 2: Reducing Maintenance Time in Heavy Machinery Production

A heavy machinery producer discovered that their existing hot tap machine was prone to clogs and frequent overhauls. Upgrading to a machine from Rockwell Automation reduced maintenance time by 40% and extended the equipment's lifespan. This improved reliability allowed the company to focus on core operations without the disruptions caused by maintenance downtime.

Comparative Analysis: Top Manufacturers and Their Hot Tap Machines

Key Manufacturers to Consider

- Johnson Controls: Known for their robust hot tap solutions and automation capabilities. Their machines are designed for high-temperature applications and offer advanced control systems.

- Rockwell Automation: Offers a wide range of industrial automation tools, including hot tap machines. Their solutions are flexible and customizable, making them suitable for various industries and processing needs.

- Schneider Electric: Provides energy-efficient and scalable hot tap solutions. Their designs focus on reducing energy consumption and ensuring long-term reliability.

Advantages of Different Models

- Johnson Controls: High durability and advanced control systems.

- Rockwell Automation: Flexible and customizable solutions.

- Schneider Electric: Energy-efficient designs and long-term reliability.

Choosing the Best Hot Tap Machine

Recap of Key Factors

- Material compatibility: Essential for handling hot fluids without degradation or corrosion.

- Durability and maintenance: Ensures long-term efficiency and reduces downtime.

- Efficiency and productivity: Drives operational success and reduces waste.

- Cost-effectiveness: Balances initial investment with long-term savings.

- Safety standards: Non-negotiable for safe and compliant operation.

Final Thoughts on the Importance of a Hot Tap Machine

Hot tap machines are the backbone of modern manufacturing, enabling precision, safety, and efficiency. By carefully evaluating your needs and selecting the best hot tap machine, you can optimize your production processes and achieve sustainable growth. Ensuring that your equipment meets the highest standards of performance and safety is not just an investmentit's a strategic move towards long-term success.

Final Thoughts: A Manufacturer's Perspective

The Journey Ahead

The future of hot tap technology is evolving rapidly, with advancements in automation, energy efficiency, and material science. Manufacturers who embrace these innovations will stay ahead of the competition. Embracing new technologies will not only enhance operational efficiency but also position your business for sustained growth and excellence.

Closing Remarks: Embracing Innovation

Innovation in hot tap machine technology will continue to drive efficiency and productivity. By staying informed and making strategic choices, manufacturers can unlock new possibilities and set the stage for a successful future.