How Hot Tapping Companies Address Customer Concerns and Issues

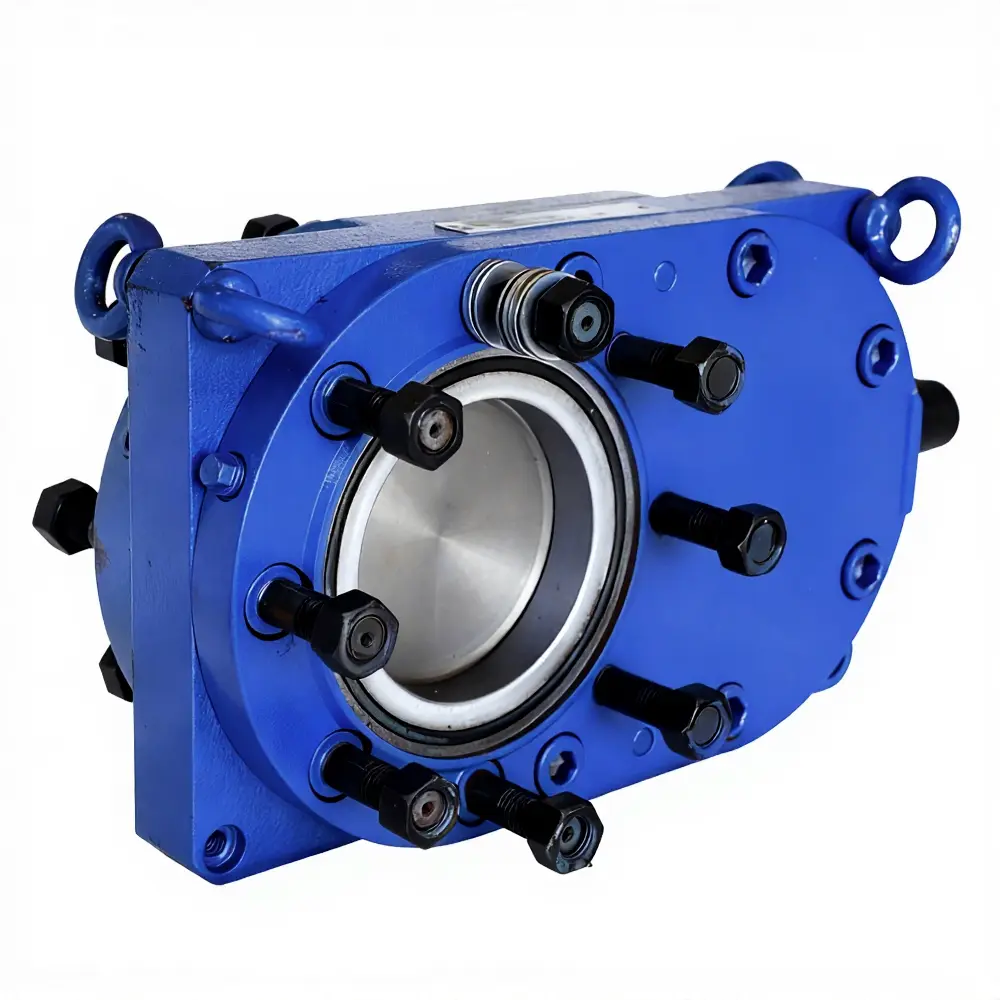

To prevent issues from arising, hot tapping companies employ forward-thinking maintenance strategies. By implementing advanced tools and technologies, such as predictive analytics and regular equipment inspections, they identify potential problems before they escalate. Predictive maintenance allows for timely interventions, reducing unexpected breakdowns and extending the lifespan of machinery. For example, using sensors and monitoring systems, these companies can track equipment performance in real-time, detecting anomalies and recommending preventive measures. This proactive approach not only minimizes downtime but also enhances operational efficiency, ensuring machinery runs smoothly and reliably.

Clear and Transparent Communication

Expertise and Training

Continuous Improvement

Specific Example

Consider a scenario where a manufacturing plant experienced frequent pump failures, leading to significant downtime and increased operational costs. A hot tapping company was brought in to assess the situation. Through a thorough analysis of the machinery, they identified specific issues and recommended a predictive maintenance strategy involving advanced monitoring systems. The company also provided detailed training to the plants maintenance team to ensure they could perform regular checks and preventive maintenance. As a result, the plant saw a significant reduction in downtime and an increase in overall equipment effectiveness.

Conclusion

This comprehensive approach not only resolves issues swiftly but also builds enduring relationships, making hot tapping companies indispensable partners in industrial maintenance and operations.