Hot Tapping Companies Leverage Cutting-Edge Technology

In the modern industrial landscape, hot tapping companies are leading the charge in ensuring operational continuity and safety. This innovative technique involves making precise modifications to pressurized pipelines without shutting them down, making it indispensable for various industries such as oil and gas, water and sanitation. Hot tapping is critical because it enhances efficiency, reduces downtime, and ensures the integrity of critical infrastructure.

Technological Advancements in Hot Tapping

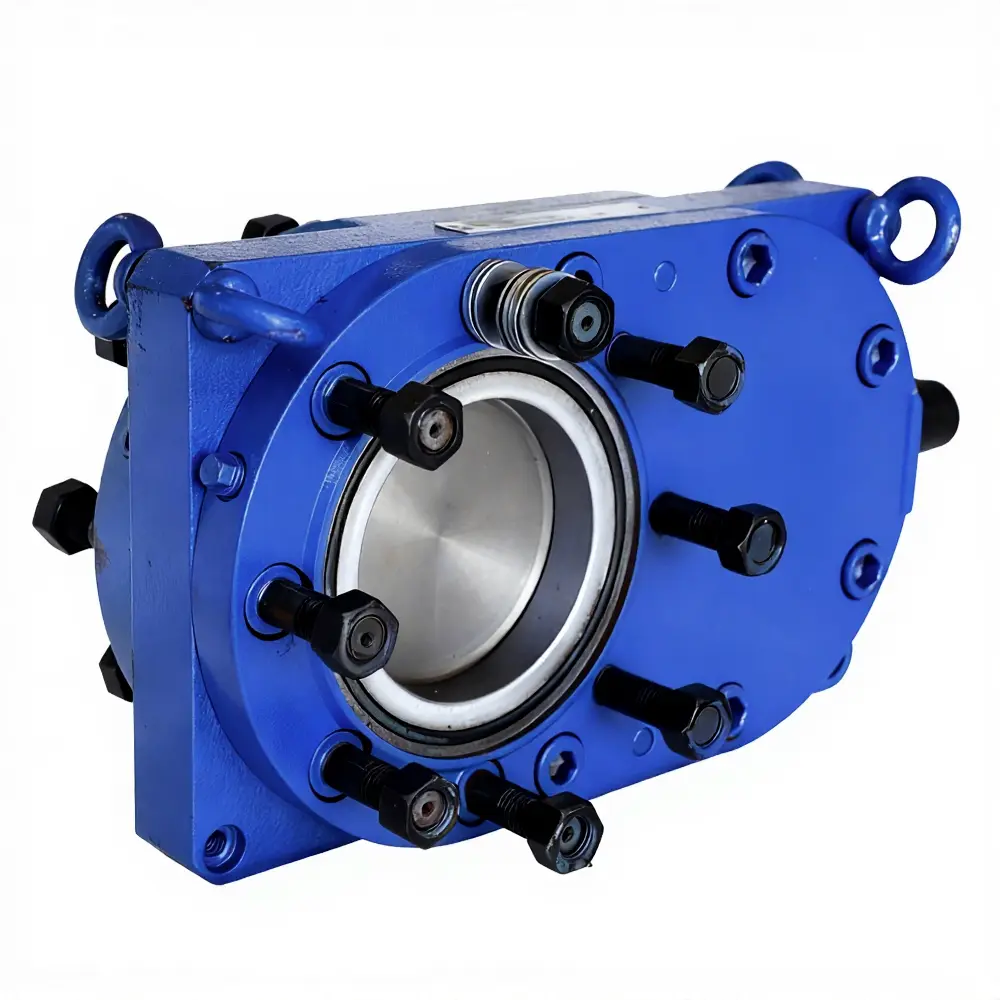

Advancements in hot tapping tools have transformed this field, offering unprecedented precision and safety. Remote-Controlled Cutting Systems allow for precise operations even in hard-to-reach areas, ensuring minimal disruption during modifications. Laser-Guided Machinery further enhances accuracy, providing real-time feedback to operators. Intelligent Robotic Arms provide real-time data monitoring, ensuring continuous oversight and swift identification of any potential issues.

Case Study: XYZ Tapping Services

XYZ Tapping Services recently modified a pressurized gas pipeline to install a new valve, demonstrating the real-world benefits of modern hot tapping technology. By utilizing advanced laser-guided cutting tools and real-time monitoring systems, the team completed the task with minimal disruption and adhered to strict timelines.

- Precision Cutting: The use of robotic arms ensured cutting with exceptional precision, minimizing risks of leaks or damage to the pipeline.

- Safety: Real-time monitoring systems provided continuous oversight, reducing the likelihood of accidents or errors.

- Cost Efficiency: Reduced downtime and fewer errors led to significant cost savings, illustrating the economic advantages of modern technologies.

Traditional vs. Modern Hot Tapping Methods

While traditional methods have served their purpose over the years, modern techniques offer marked improvements in terms of efficiency, safety, and economic viability. Precision and Safety: Modern tools offer higher precision and can operate in challenging environments, reducing the risk of accidents. Cost Efficiency: Reduced downtime and fewer errors make modern methods more economically viable. Regulatory Compliance: Modern techniques better align with current regulatory standards, ensuring safer operations.

Impact of Technology on Industry Standards

The adoption of new technologies in hot tapping is driving significant changes in industry standards and practices. Regulators and industry bodies are increasingly recognizing the need to update standards to accommodate these advancements. Hot tapping companies must ensure their practices meet or exceed current standards, contributing to the development of new industry best practices that prioritize safety and efficiency.

Future Trends in Hot Tapping Technology

Looking ahead, the future of hot tapping technology holds several exciting trends. Automation and Enhanced Data Analytics are set to transform the industry, reducing human error and providing deeper insights into operational performance. Improved Material Science will further enhance the durability and integrity of pipelines.

Despite these challenges, the potential benefitsimproved safety, greater efficiency, and enhanced operational performancemake the investment in modern technologies well worth it.

Conclusion

Hot tapping companies are leading the transformation of pipeline maintenance by leveraging cutting-edge technology. As these companies continue to innovate, the industry will experience significant improvements in safety, efficiency, and operational performance. The future is bright for these companies, and their technologies are paving the way for a more intelligent and sustainable future. Embracing these advancements is not just about survival; it is about setting the direction for how we will maintain and upgrade critical infrastructure in the years to come. The impact of their innovations is just beginning to be realized, and this is only the start of a promising journey.