What Hot Tapping Companies Should Include in Their Service Packages

Hot tapping is a vital process for maintaining and expanding industrial operations without halting existing systems. To ensure safety, efficiency, and compliance, hot tapping companies must offer comprehensive service packages tailored to meet the unique needs of their clients. This article will explore the key components that hot tapping companies should include in their service packages to deliver exceptional service and reliability.

Understanding Hot Tapping: A Comprehensive Introduction

Hot tapping technology has revolutionized the way industrial operations are maintained and expanded. This process allows new equipment or services to be introduced into existing pipelines while the system remains operational. It is particularly crucial for industries such as oil and gas, chemical processing, and utilities, where downtime can be extraordinarily costly. Comprehensive service packages are indispensable for ensuring that hot tapping operations are conducted safely and efficiently, meeting both regulatory standards and the specific needs of clients.

Safety and Compliance: Essential Components of Hot Tapping Services

Advanced Tools and Techniques: Enhancing Hot Tapping Efficiency

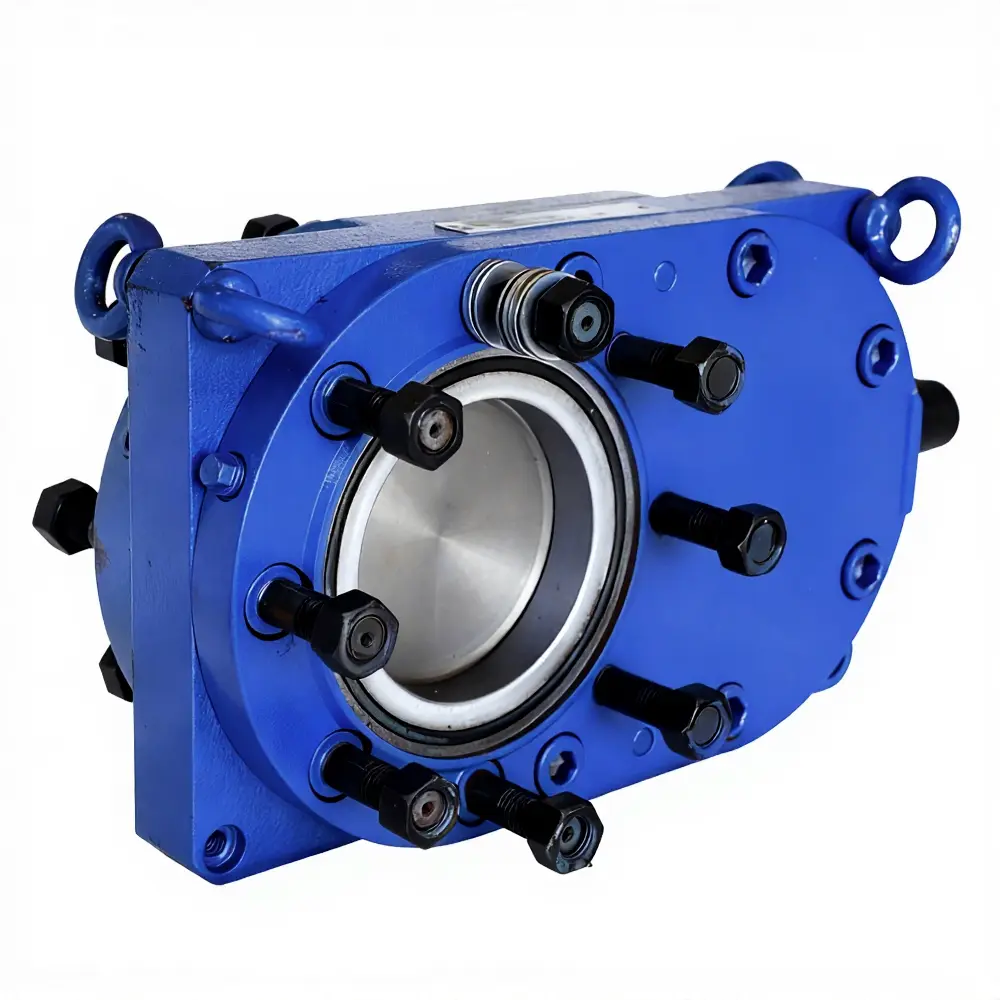

The use of advanced equipment and tools is paramount in ensuring the success of hot tapping operations. High-quality, specialized tools like cutting heads, plugging heads, and welding equipment are essential for precise and safe cutting and sealing. Regular maintenance and calibration procedures ensure that these tools remain reliable and effective. Leading-edge technology not only speeds up the process but also reduces the risk of errors, thereby minimizing downtime and costs.

Innovation and Expertise: Driving Hot Tapping Success

Technical skills and innovation are key drivers of success in hot tapping operations. Staying updated with the latest technologies and methodologies ensures that companies can offer the most efficient and effective solutions to their clients. For instance, the introduction of robotic systems and smart tools can significantly streamline the process. A company that implemented such technologies could not only enhance precision but also reduce the time required for the process by 30%.

Tailored Solutions: Customizing Hot Tapping Packages for Your Needs

Every client has unique requirements and industry-specific challenges. Comprehensive service packages should be customized to meet these needs. This involves consulting with clients to understand their specific requirements and tailoring the service package accordingly. For example, in the oil and gas industry, the service package might include specialized equipment for high-pressure environments, while in the chemical processing industry, it might include additional safety measures and adherence to specific regulations. Providing tailored solutions not only meets the client's needs but also demonstrates a commitment to excellence and reliability.

Emergency Preparedness: Safeguarding Hot Tapping Operations

Preparedness is key in hot tapping operations. An emergency response plan is critical for minimizing downtime and ensuring the safety of operations. Strategies for handling unexpected issues should be clearly defined and practiced. Best practices for rapid resolution, such as having a well-stocked emergency kit and a trained team on standby, can help mitigate the impact of any issues that arise. By prioritizing emergency preparedness, hot tapping companies can ensure minimal disruption and continued service reliability.

Commitment to Excellence: Continuous Improvement in Hot Tapping Services

Continuous improvement and ongoing training are essential for maintaining high standards of service and safety. Ongoing training programs for technicians and staff ensure that everyone is up-to-date with the latest techniques and technologies. Quality management and continuous improvement initiatives help identify areas for enhancement and ensure that the company is always meeting best practices. A company that implemented a robust training program could significantly reduce errors and enhance client satisfaction.

Wrapping Up

Comprehensive service packages are the cornerstone of successful hot tapping operations. By prioritizing safety measures, investing in advanced equipment and tools, fostering technological expertise and innovation, providing customer-specific solutions, ensuring emergency preparedness, and committing to continuous improvement, hot tapping companies can deliver exceptional service to their clients. This holistic approach not only enhances operational efficiency and safety but also builds strong, long-lasting relationships with clients, ensuring the continued growth and success of the company.