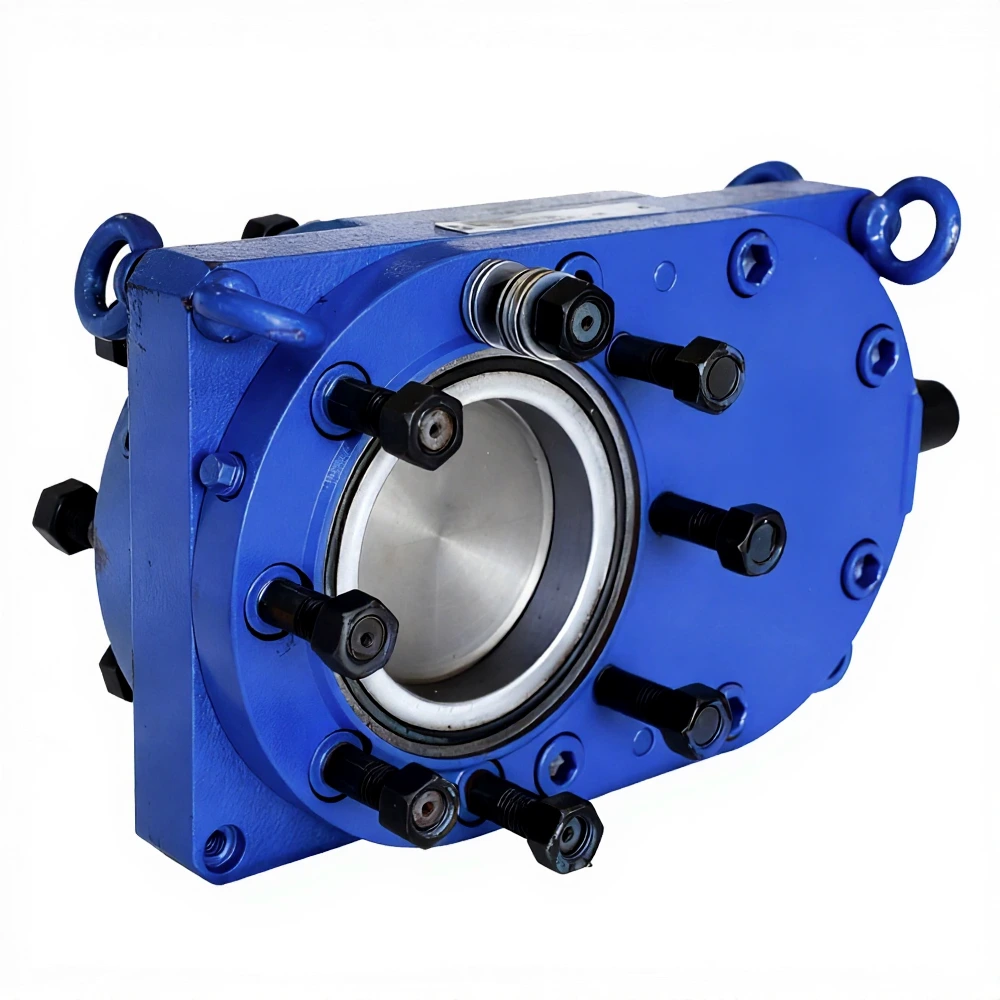

SV100 Wafer Valve Taitat Changlin Pipeline

The wafer valve is designed for use with Taitat Changlin Tapping, Plugging Machines, and fittings during hot tapping and plugging (HT&P) operations. Wafer Valves have a flat faced, serrated gasket surface and are supplied to match ASME class 150, 300, or 600 flanges.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Key Features

● Bidirectional design allows for installation in any direction.

● Can be oriented parallel or perpendicular to the pipeline to fit the excavation.

● Equipped with an oversized bore, positive shutoff, built-in pressure equalizing valve and integral flange studs.

Specifications

| Pipeline Medium Temperature | -20-80°C |

| Applicable Media | oil, natural gas, water, coal gas, light oil, aviation fuel, and other non-corrosive media |

| Valves 16-inch and larger are hydraulically operated | |

| Engineered to match ASME Class 150, 300 or 600 flanges | |

| 4-inch through 28-inch | |

Common Applications

Hot tapping and isolation operations, including tie-ins, crossovers, line extensions, connections, main relocations, and bypasses.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact Us

For over 40 years, we have provided safe, efficient, and proven solutions for pressure pipeline systems worldwide.

● Projects: 20000+

● Factory Area: 75000 m²

● Technical Personnel: 80+

● NEEQ: 25/1/2018

● Patents and Certifications: 54

Fill in the information

Related Products

no data

links

Products

Contact with us

WhatsApp: +86 13570819716

E-mail: ttclpipeline@gmail.com

Add: NO.1208 Saiwei Avenue, EDZ, Xinyu City Jiangxi Province, China.

Copyright © 2025 Taitat Changlin | Sitemap | Privacy Policy