Main Products

no data

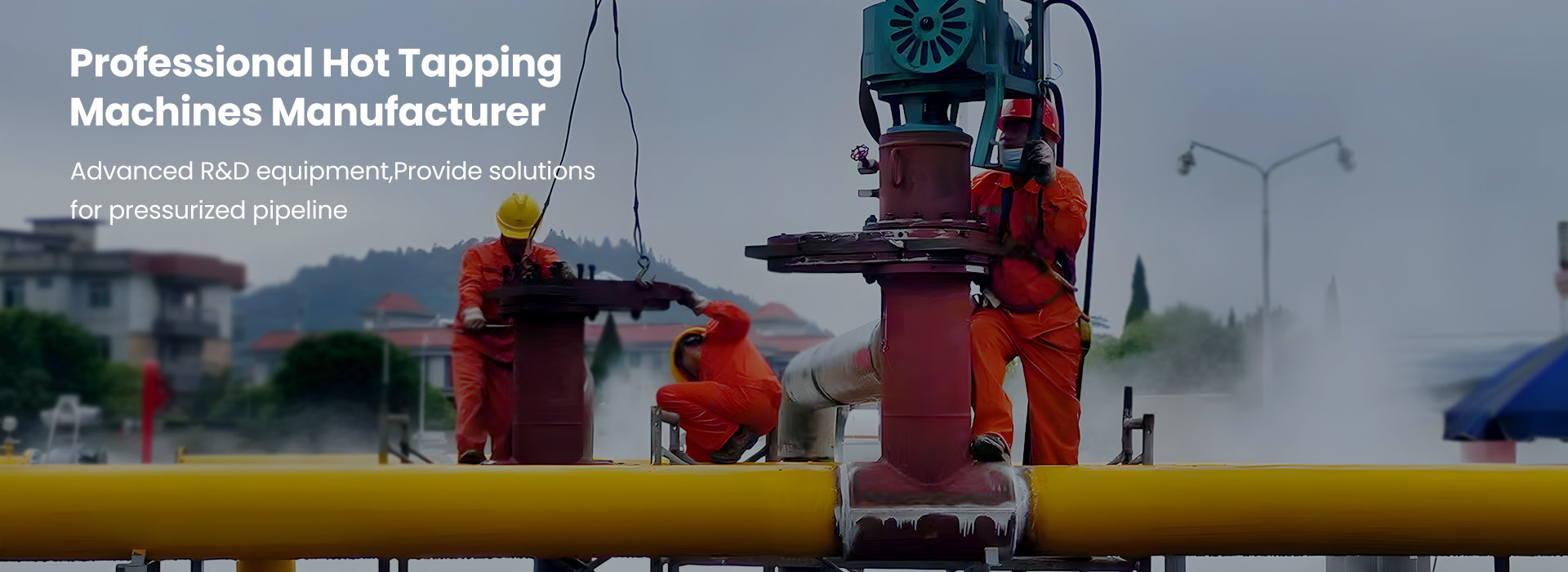

Used to make a new connection into a live pipeline, our hot tapping machines can be used on a wide array of pipeline diameters, pressures and compositions in any environment.

no data

Service Cases

We have provided safe, efficient, and proven solutions for pressure pipeline systems worldwide.

no data

since

1982

Taitat Changlin Pipeline Technology (Jiangxi) Co., Ltd. is dedicated to the R&D, manufacturing and on-site services of hot tapping and line plugging equipment. Spanning an area of 75,000㎡, our facility houses over 150 professionals, including more than 80 technical experts.

With a legacy dating back to 1982, we have completed 20000+ projects to date. On January 25, 2018, the company officially listed on the national equities exchange and quotations (NEEQ).

For more than four decades, we've delivered safe, efficient and battle-tested solutions for pressurized pipeline systems worldwide. Our work maximizes operational uptime, eliminates costly shutdowns and guarantees the secure delivery of energy - all while keeping systems running smoothly.

Overall factory environment

Equipped with intelligent production lines and advanced R&D equipment, we achieve both high-efficiency production and rigorous processes.

no data

Partner Brands

no data

our Certification

Won a number of national qualifications, and its brand strength is highly recognized.

Contact Us To Get Competitive Price

Copyright © 2025 Taitat Changlin | Sitemap | Privacy Policy